| |

Innovation Follows Program

World population by 1960 was about to burst at the seams. Or so it

seemed. Capping the dramatic population increases of the first half of the 20th

century, the 1950s' baby boom intensified people’s sense of an earth that

was shrinking. Metropolitan centers in particular were pressed for space.

Housing was needed

| |

| |

|

| |

| |

The revolutionary framed-tube structural system was first seen in the construction of the DeWitt-Chestnut Apartments.

|

| |

for a large number of people — single-family homes

were not sufficient — and office space was also wanted for the spiraling

numbers of office workers. A healthy economy ensured a sustained demand for

office space.

High-rise construction offered the perfect solution. Super-tall

buildings could provide large amounts of floor area without having to be

densely packed, one building upon the next. A portion of each city block that a

high rise occupied could be left available for desirable city plazas and parks.

Despite these apparent advantages, super-tall building

construction faced a critical deterrent: expense. Skyscrapers were simply too

costly by modern development standards. A tower reaching as high as the Empire

State Building could not be justified in economic terms.

It was a generally accepted "fact" of construction that

taller buildings cost more to build per square foot of rentable floor area than

shorter buildings. A rapid run-up in structure costs resulted from increased

wind forces: in order to withstand greater wind effects, a tower's structural

framework had to be strengthened and stiffened considerably with increasing

building height. Developers, therefore, were dissuaded from building above the

thirty-story range by this cost premium. They leaned instead toward

constructing bulky, site-consuming edifices. It appeared that conditions in

central business districts were bound to worsen, with every building site being

completely filled.

It was at this critical moment in the development of the modern

urban environment that Fazlur Khan entered the profession.

Filled with both ambition and optimism, and equipped with solid

training in structural engineering, Fazlur Khan was undeterred by the

mindset and technological difficulties that hindered tall building design.

He recognized that the structural systems utilized for high-rise construction

were not on a par with the modern scale of architecture,

| |

|

| |

|

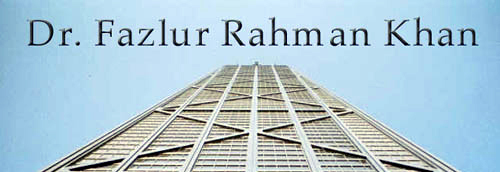

In 1960, buildings over 20 stories were still newsworthy; by the close of the decade, people were "living in the sky." Apartments in the John Hancock Center in Chicago are located as high as the 90th floor.

|

| | |

and he took

on the challenge of advancing state-of-the-art structural engineering. A decade

of revolutionary advances had just begun.

Fazlur Khan's earliest contributions to the field — developing the

shear wall frame interaction system, the framed-tube structure, and the

tube-in-tube structure —

| |

| |

|

| |

| |

The Onterie Center in Chicago interpreted the trussed-tube structural system for reinforced concrete construction.

|

| |

led to significant improvement in structural

efficiency: they made the construction of tall buildings economically feasible.

The framed-tube structure has its columns closely spaced around the perimeter

of the building, rather than scattered throughout the footprint, while stiff

spandrel beams connect these columns at every floor level. This structural

system was first implemented in 1964 in the construction of the DeWitt-Chestnut

Apartments in Chicago, a 43-story reinforced concrete tower designed by Fazlur

Khan and his colleagues at Skidmore, Owings & Merrill (SOM). Because of its

great relative strength and stiffness, the tubular form immediately became a

standard in high-rise design.

As the reach of tall buildings extended, Fazlur Khan resolved to

discover structural systems appropriate for each new scale of architecture.

Crafting rational architecture in cooperation with Bruce J. Graham, chief

design architect in SOM's Chicago office, he united an exceptionally efficient

"trussed-tube" structural system with an articulate, graceful form

for Chicago's 100-story John Hancock Center.

| |

|

| |

|

Looking up at the Sears Tower, the world's tallest building for over twenty years. The design for this 1450-foot-tall tower introduced the bundled tube structural system, as well as a new vocabulary in architectural form.

|

| | |

A few years later he introduced another groundbreaking structural

system, the "bundled tube." This design for Chicago's 110-story Sears

Tower was structurally efficient and economic: at 1,450 feet, it provided more

space and rose higher than the Empire State Building, yet cost much less per

unit area. Equally important, the new structure type was innovative in its

potential for versatile formulation of architectural space. Efficient towers no

longer had to be box-like; the tube-units could take on various shapes and

could be bundled together in different sorts of groupings.

When one looks at a text on tall-building design today, one finds

these recognizable structure types: the framed tube, the shear wall frame

interaction, the trussed tube, the bundled tube, and the composite system (also

developed by Fazlur Khan). Though Khan developed structural systems for

particular project needs, he based his innovations on fundamental structural

principles that allowed them wide application. His developments are among

today’s “conventional” systems for skyscraper design.

| |

| |

|

| |

| |

Saudi Arabia celebrated its new airport terminal in a postage stamp design.

|

| |

As the building boom in the West came to an abrupt halt in 1974,

new demands surfaced that thrust designers into unfamiliar settings. Clients in

the Middle East and Asia, for example, were anxious and now financially able to

construct housing, offices, and other facilities in large scale. SOM took on

this design work, and Fazlur Khan responded to needs and situations as he

perceived them.

For the immense roof of the Hajj Terminal of the new airport in Jeddah,

Saudi Arabia — intended to shelter 80,000 pilgrims at a time, waiting

for up to 36 hours — he searched for a coherent scheme that was both

efficient and honored the spirit of the Hajj pilgrimage. The fabric roof

structure melds a traditional concept, that of the Bedouin tent, with

sophisticated technology. Twenty years after the airport's opening, this

fabric roof and the space that it creates continue to awe as well as comfort

terminal users.

|